Japan´s Eneos Corporation, one of Asia´s leading integrated energy company, begins operation next month of a demonstration plant in Brisbane, Queensland state, Australia, towards the development of a CO2-free Hydrogen Supply Chain.

The new plant will produce methylcyclohexane, a type of hydrogen carrier, using its proprietary low-cost “electrochemical synthesis of organic hydride” method. The opening ceremony was held in January 30 and the plant will begin operation in February.

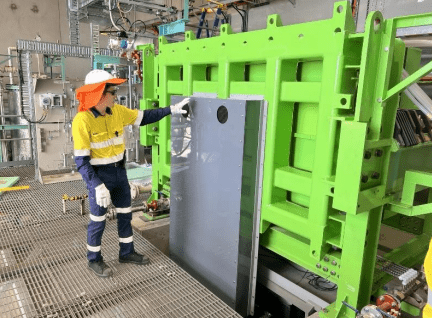

Eneos has worked to scale up electrolyzers using Direct MCH technology in order to mass produce MCH derived from renewable energy (Green MCH).

The 150-kilowatt-scale medium-sized electrolyzer (approximately 200 times larger than the electrolyzer used in the 2021 demonstration), which Eneos recently succeeded in developing the technology for, consists of stacked electrodes with a surface area of 3 square meters. The electrolyzer realizes increased efficiency in MCH production with electrodes which are nearly the largest by size that is used industrially, as the company mentions.

The demonstration plant will produce green MCH by combining the medium-sized electrolyzer with a 250-kilowatt solar power system in Queensland, which is ideal for solar power generation.

With the aim of maximizing production efficiency, the plant will confirm the durability of the electrolyzer under subtropical conditions as well as develop optimal operation and control technologies for it when plant operation is adjusted to match fluctuations in solar power during the approximately eight-month-long demonstration period from February to September 2023.

Additionally, during the demonstration period, MCH equivalent to approximately 2 to 3 tons of hydrogen for 400 to 600 fuel cell vehicles (FCVs) will be produced and transported to Japan, where hydrogen will be extracted from MCH in Eneos´ Central Technical Research Laboratory.

Eneos will use the knowledge gained from this demonstration plant to develop a larger-sized 5 megawatt-scale electrolyzer (more than 30 times larger than the medium-sized electrolyzer used in this demonstration plant) for commercialization by February 2025.