Canada Steamship Lines (CSL), the Montreal headquartered ship owner and operator of self-unloading vessels, has announced a 20-year strategic partnership with Australian-based Adelaide Brighton Cement (Adbri) to build and operate the world’s first fully electric battery capable self-unloading vessel.

The custom-designed ship will begin construction in 2024 and her delivery is expected in early 2026.

The self-unloading newbuilding will, as per company information, replace Adbri’s “Accolade II” and support the company’s limestone operations in South Australia, where the newbuild vessel will carry up to 2.7 million tonnes of limestone per year, which represents a 35% increase over the existing vessel’s carrying capacity.

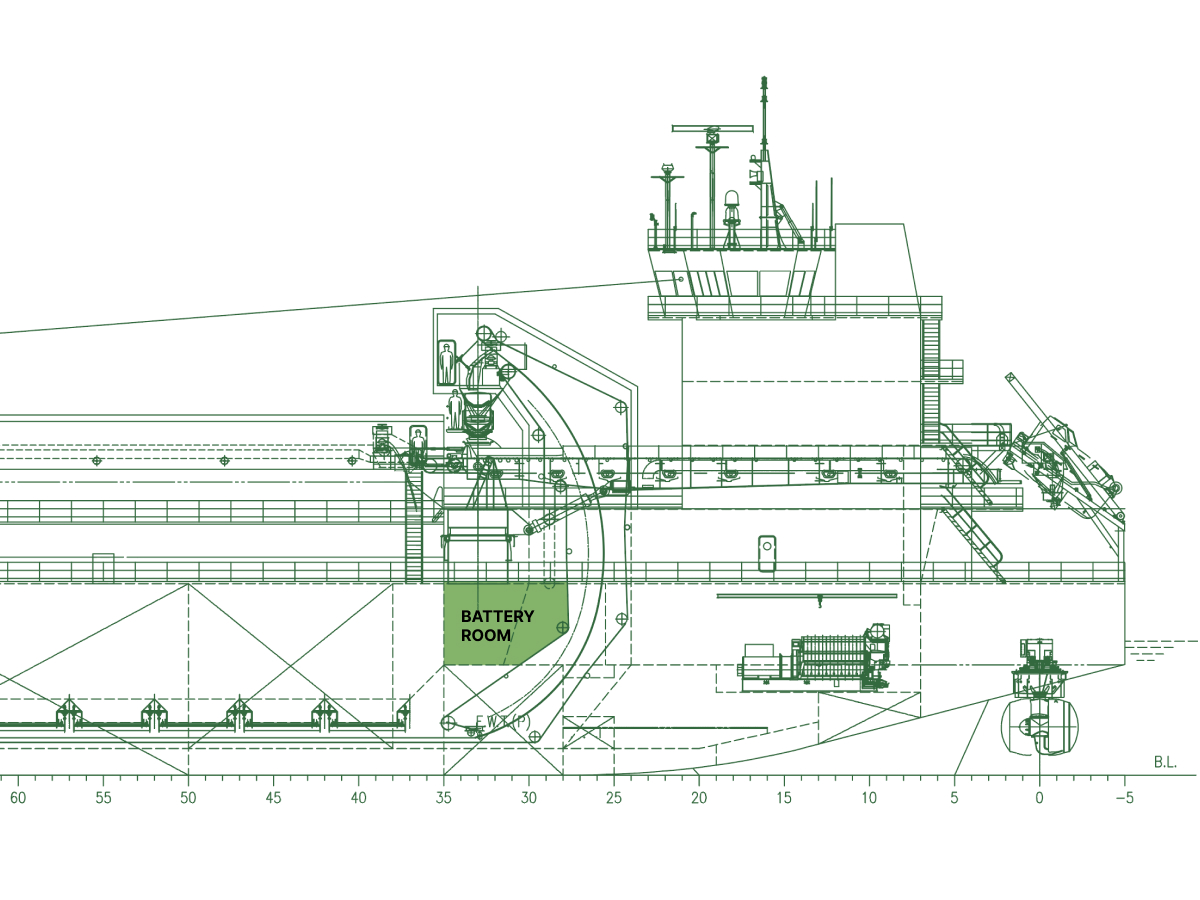

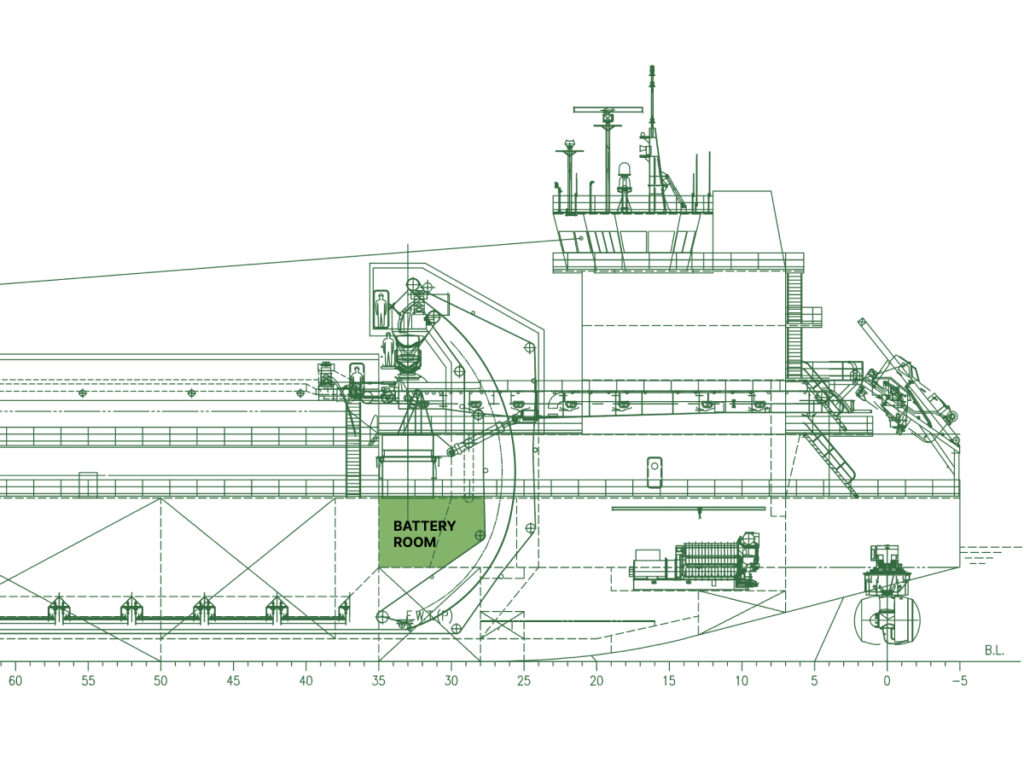

In accordance with CSL, the design of the 11,000 dwt self-loading and self-discharging bulk carrier has been optimised to provide a fully integrated limestone supply chain for Adbri.

“The hybrid diesel-electric propulsion system combined with one of the most advanced battery installations on a bulk carrier globally provides a pathway to decarbonise the shipping operations.”

CSL mentions that approximately 50% of the vessel’s energy requirements will be provided by a combination of shore power and battery energy storage, with plans to install sufficient batteries in the future to allow 100% electric operations.

Louis Martel, CSL president and chief executive, explained: “Developed in line with CSL and Adbri’s shared decarbonization vision, this groundbreaking vessel will initially run on a hybrid diesel and battery system, replacing 25% of diesel with electric power and lowering Scope 1 emissions by 40% compared to Accolade II,” and he adds that “By 2031, we aim to run the ship entirely on electric power, further reducing Scope 1 emissions to less than 10%.”

Mark Irwin, chief executive of Adelaide Brighton Cement, said: “Adbri is excited to have one of the world’s first 100% battery electric capable cargo vessels as our limestone carrier,” adding that the new vessel, owned and operated by CSL, will support Adbri to increase cement volumes at Birkenhead, while also supporting the production of lower carbon products such as EvoCem™ that uses limestone as a clinker substitute.